Advancing Nanomaterials from Lab to Market: Ablano’s Journey

Advancing Nanomaterials from Lab to Market: Ablano’s Journey

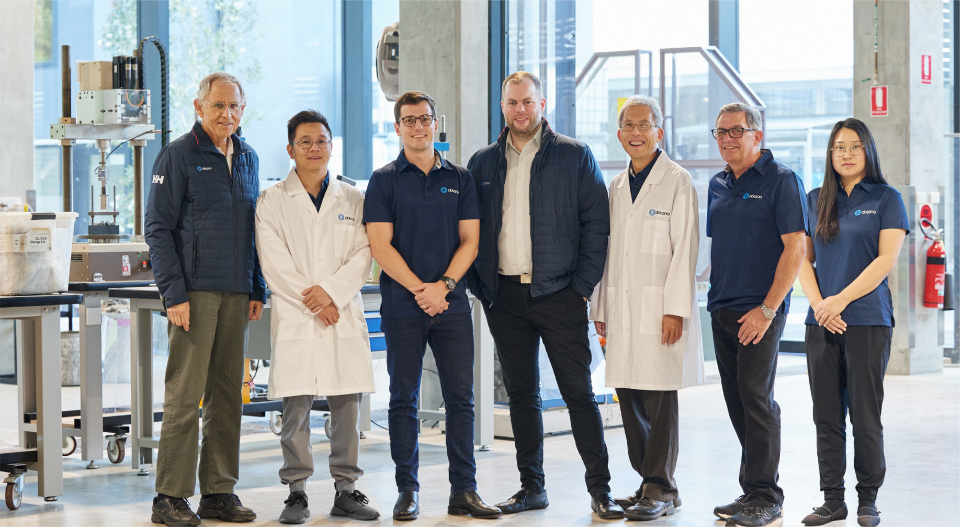

Ablano Co-Directors, Professor Hui Tong Chua and the research team

In a world increasingly reliant on advanced technologies, from quantum computing to robotics and aerospace; traditional materials like silicone, plastics, and composites are reaching their limits. Bridging this gap requires innovation at the nanoscale level. Ablano is a UWA spin-out company on a mission to transform precursor powders into next-generation nanomaterials that could revolutionise industrial lubricants, coatings, and beyond.

Backed by deep scientific expertise from Professor Hui Tong Chua and his research team at UWA’s Department of Chemical Engineering, Ablano has spent the past five years maturing its technology and is committed to the commercial scale-up manufacturing of few-layer graphene and boron nitride nano onions.

- Few-layer graphene are layers of carbon atoms that are chemically separated from natural graphite which is then manufactured into a dark coloured powder. The powder can be added to composite materials to enhance mechanical strength and used in noise suppression applications.

- Boron nitride nano onions is a synthesised white powder which is produced by exposing precursor powders to Ablano’s patented lamp ablation technology. Layered spherical molecular compound structures that resembles an onion are formed that will be ideal as a high-performance ceramic hollow nano ball bearings. “This essentially means the nanoparticles in the powder form a frictionless surface that will act as a super lubricant”, Professor Chua explains.

Professor Chua is a global leader in chemical engineering and achieved major success as one of the key engineers behind the Hazer Process. Read more about Hazer.

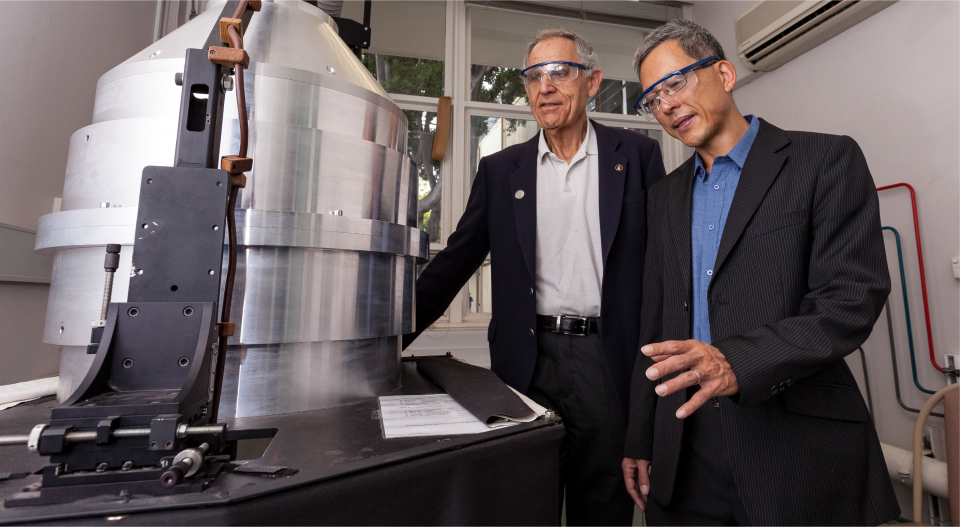

Ablano’s patented lamp ablation technology

Cracking the code for scalable nanomaterials

“There’s only so far traditional materials can go,” says Michael Rimbas, one for the Directors at Ablano who brings a finance background and an investor’s perspective to the group. “Emerging fields like quantum, drones, and robotics are creating a clear driver for change.” Ablano’s flagship innovation that centres on boron nitride nanomaterials, promises significant efficiency gains, reducing emissions, conserving resources, and extending product lifespans. For example, demanding moving parts, such as wind turbines and marine engines that experience high contact pressure will benefit from lubricants with a boron nitride nano onions additive. With the global lubricant market alone projected to reach USD 205 billion by 2032 (Fortune Business Insights, 2025), the potential impact is enormous.

The company has since moved from lab-scale experiments to a 400 sqm pilot facility in Perth’s northern suburbs. Their commercialisation strategy includes:

- licensing or selling boron nitride nanomaterials,

- offering the transformation process of precursor materials and/or,

- developing end-use products like advanced paint coatings.

Ablano Co-Directors, Michael Rimbas & Thomas Symes

Powering progress through research infrastructure

Ablano’s rapid progress is fuelled by its close collaboration with UWA’s Centre for Microscopy, Characterisation and Analysis (CMCA). Open access to advanced instruments such as transmission electron microscopes (TEM) and high-resolution scanning electron microscopes (SEM) enables researchers to visualise material structures at the nanoscale. Raman spectroscopy, meanwhile, uses laser-induced energy shifts to identify and characterise materials, such as determining the number of graphene layers with high precision. These platforms have been critical to the growth and continued success of Ablano.

“These instruments, typically out of reach for most start-ups have allowed us to ascertain the quality of our products, ensuring that we continue on our path to commercialisation.”

Professor Professor Hui Tong Chua, UWA

The partnership goes beyond equipment. Ablano sponsors two former PhD researchers from UWA’s Chemical Engineering department, now full-time research associates and have had expert technical guidance from researchers including Associate Professor Martin Saunders from CMCA. “Their technical expertise and familiarity with CMCA’s instrumentation have been essential in pushing our technology closer to market” says Michael.

Looking ahead: commercial milestones and broader impact

Since its incorporation through the UWA Office of Industry and Commercial Development in 2021, Ablano has secured patents across multiple international jurisdictions and raised nearly $4 million in capital. With aspirations for an ASX listing and a product launch within the next 12 to 24 months, the company is poised for broader recognition.

Michael and the Ablano team remain committed to collaboration with UWA, engaging with students and researchers, and leveraging open-access research infrastructure. Their initial focus is on aviation-grade lubricants, with future applications in marine, industrial coatings, and even cancer therapies where boron nanomaterials may help reduce tumour sizes. Michael’s advice to others considering research partnerships? It’s quite simple, “Start with a conversation; open dialogue is key to getting what you need!”

Catching corporate fraud: a Systems Intentionality approach

Catching corporate fraud: a Systems Intentionality approach